Welcome

Read About It+

Super Pumping (SP) has the experience to provide a vast array of products targeting the growing global market. SP is bringing advances to the Turbine and Pump industry with computer modeling as well as harmonic sensors and wireless technology with scalable options that are bringing turbines and pumps into the future and with its retail division, Super Pumpingwill allow us to expand exponentially.

Our Mission

Read About It+

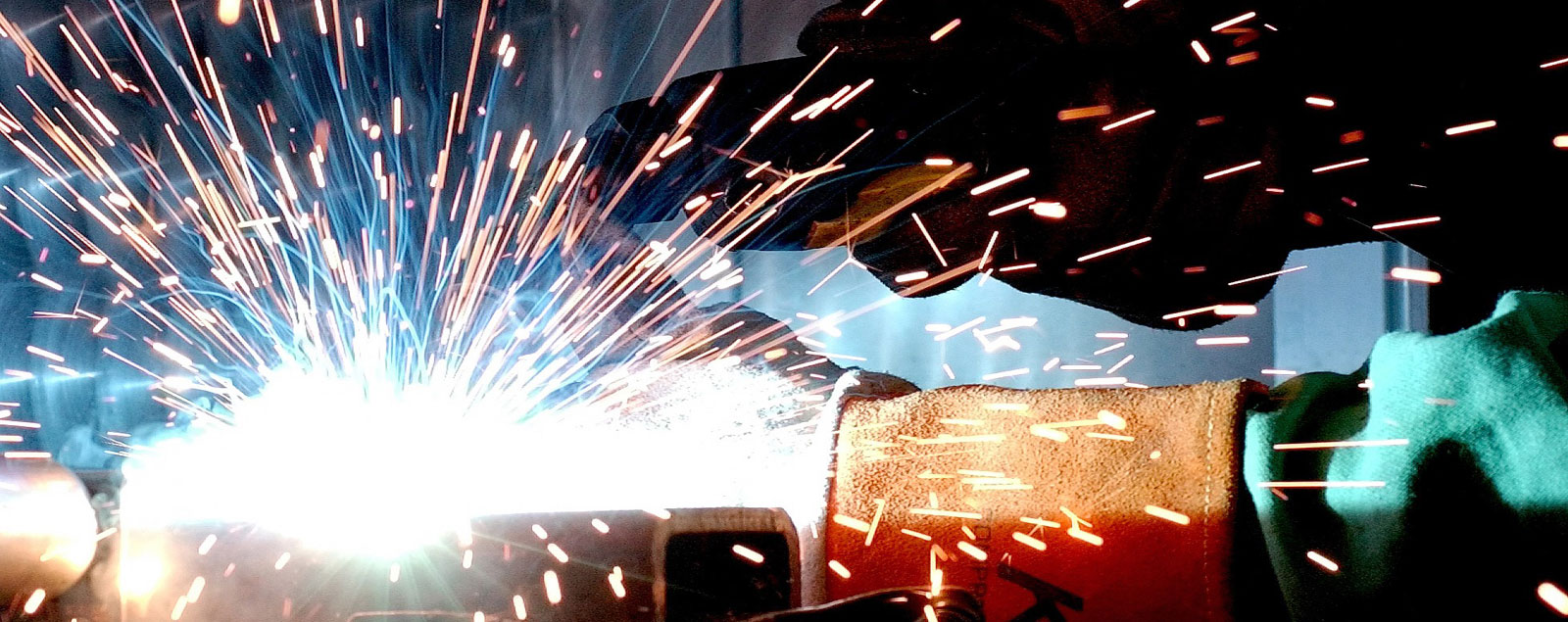

Super Pumping (SP) is filling the gap... a missing link in ever increasing industry needs ..we are here to define high tech custom turbine fabrication using our in house mfg factory and network of leading industry OEMs.

Our Pump Technology

Read About It+

Super Pumping’s rotating machinery technology plays an important role in the downstream industry. Plant process conditions are often severe. A typically sized topping unit may provide output capability of 1,500 tons per hour.

Critical process points, such as those for furnace charge pumps that face temperatures near 800 C, require special technological solutions. A fluid catalytic cracking (FCC) plant requires the feed to be mixed with the catalyst and then pumped to the reactor with temperatures around 500C.

Air required by the process is normally supplied by centrifugal or axial compressors with normal flow around 50,000 normal cubic meters per hour (Nm3/h). Power requirements also may reach several megawatts. Rotating machinery for compression and pumping applications plays a critical role in determining the overall robustness of the plant. Centrifugal pumps, being present in almost all plant processes, are especially important.